Table of Contents

- Impact of Manufacturing Processes on Ecosystem Health

- Challenges of Solar Panel Disposal and Recycling

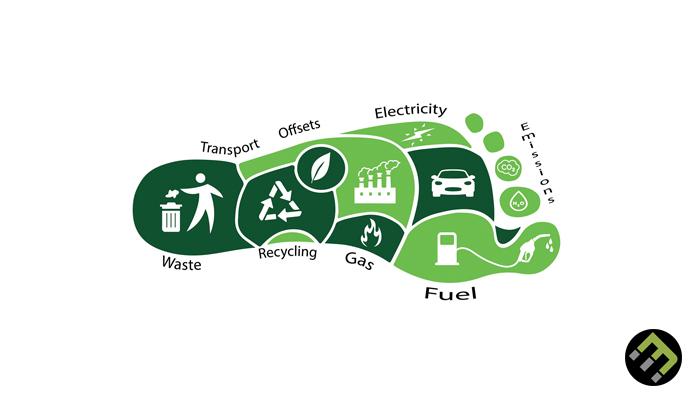

- The Carbon Footprint of Solar Panel Production

- Rare Earth Materials: Environmental Concerns and Alternatives

- Mitigating Environmental Risks: Best Practices for Sustainable Solar Energy

- Q&A

- Closing Remarks

Impact of Manufacturing Processes on Ecosystem Health

The manufacturing of solar panels involves various processes that can significantly influence ecosystem health. From the extraction of raw materials to the final assembly, each stage comes with environmental repercussions. For instance, the mining of silicon, a primary component in solar cells, often results in habitat destruction and landscape alteration. This can lead to a decline in local biodiversity as native species are displaced or affected by the pollution generated during mining operations.

Additionally, the processing stages often require significant energy inputs, which may come from nonrenewable sources, further contributing to carbon emissions. The following factors are critical in understanding the overall impact:

- Chemical Use: Manufacturing involves hazardous substances that can contaminate air and water sources if not managed properly.

- Waste Generation: The production process generates waste materials, including potential toxins that can seep into the environment.

- Water Consumption: High water usage in manufacturing processes can strain local water resources, particularly in arid regions.

| Manufacturing Process | Environmental Impact |

|---|---|

| Silicon Mining | Habitat destruction, biodiversity loss |

| Chemical Processing | Air and water pollution |

| Panel Production | Energy intensive, carbon emissions |

Considering these impacts, it becomes clear that while solar panels offer a sustainable alternative for energy production, the environmental costs associated with their manufacturing are substantial. Stakeholders in the solar industry must prioritize sustainable practices and innovations that minimize these negative effects, ensuring that the push for renewable energy does not come at the expense of our ecosystems.

Challenges of Solar Panel Disposal and Recycling

As solar energy adoption continues to grow, so does the concern surrounding the end-of-life management of solar panels. Many panels contain hazardous materials such as lead and cadmium, which pose environmental risks if improperly disposed of. When these products are tossed into landfills without proper handling, there is a potential for toxic substances to leach into the soil and groundwater, causing contamination. This leads to increased urgency for effective recycling programs, yet such initiatives are not uniformly established, resulting in significant disposal challenges.

Furthermore, the recycling process for solar panels is not straightforward. The technology for recycling is still maturing, and many recycling facilities are not equipped to handle the unique composition of solar panels. Some of the challenges faced include:

- High Costs: The current recycling methods can be expensive, leading to limited options for solar panel owners.

- Complex Manufacturing Materials: Solar panels are often made from various materials, including metals, glass, and polymers, which makes the recycling process complicated.

- Lack of Standard Regulations: Inconsistent regulations across regions contribute to confusion and inefficiencies in the recycling process.

Innovations in recycling technologies are essential to mitigate these issues. While some companies are pioneering techniques for recovering valuable materials like silicon, silver, and glass, most recycling methods still yield low recovery rates. A coordinated effort involving manufacturers, regulators, and consumers is crucial to develop a robust recycling ecosystem that ensures sustainable disposal practices. Here’s a simplified look at the materials typically found in solar panels and their recycling potential:

| Material | Recycling Potential |

|---|---|

| Silicon | High, widely recovered |

| Silver | Moderate, valuable but difficult to extract |

| Glass | High, commonly recycled |

| Lead | Low, requires careful handling |

The Carbon Footprint of Solar Panel Production

The production of solar panels undeniably presents some environmental challenges, significantly impacting their overall carbon footprint. While solar energy is often heralded as a clean alternative to fossil fuels, the manufacturing process requires considerable energy and resources. The key materials used in solar panels, such as silicon, silver, and other rare metals, contribute to greenhouse gas emissions throughout various stages, including extraction, processing, and transportation. This eco-impact raises questions about the sustainability of solar technology as a whole.

Research indicates that the carbon emissions produced during the manufacturing of solar panels can range significantly based on the technology and geographic location of production. For instance, different methods of silicon production can lead to variations in emissions, showcasing a wide disparity between traditional mining and newer, more sustainable extraction techniques. Below is a simplified comparison of average CO2 emissions from various solar panel production methods:

| Production Method | Average CO2 Emissions (kg CO2/kW) |

|---|---|

| Conventional Silicon Production | 1,200 |

| Thin-Film Technology | 500 |

| Recycled Silicon Production | 200 |

It’s also essential to recognize that the end-of-life disposal of solar panels poses additional environmental concerns. As solar panels have a lifespan of approximately 25 to 30 years, the increase in decommissioned panels could lead to significant waste management issues if proper recycling technologies are not developed. Current studies highlight that while there are growing initiatives focusing on the recycling of materials, there is still a lack of infrastructure and incentives to handle solar waste effectively. Therefore, while solar energy offers immense benefits in the long run, understanding the entire lifecycle of solar panel production is crucial for assessing their true environmental impact.

Rare Earth Materials: Environmental Concerns and Alternatives

The extraction and processing of rare earth materials, vital for the production of solar panels, raise significant environmental concerns. These materials, which include lanthanum, cerium, and neodymium, are essential for producing efficient solar cells and other green technologies. However, the mining operations necessary to obtain these elements often lead to severe ecological damage. Deforestation and habitat destruction can disrupt local ecosystems, while toxic waste from processing can contaminate soil and water sources, affecting both wildlife and human communities.

Additionally, the carbon footprint associated with the mining of rare earth materials cannot be overlooked. The energy-intensive processes involved in extracting and refining these elements contribute to greenhouse gas emissions—contradicting the very goals of renewable energy efforts. Heavy machinery, often powered by fossil fuels, is used to dig deep into the earth, resulting in soil erosion and increased carbon output. As these processes continue to scale with the growing demand for solar technology, the long-term sustainability of solar energy comes into question.

To mitigate these environmental impacts, exploring alternatives becomes crucial. Options such as recycling rare earth materials from old electronics or adopting solar panel technologies that rely on more abundant substances can be pivotal. Innovations in materials science may lead to the development of organic photovoltaics or thin-film technologies that require fewer harmful materials, offering a path toward greener production methods. As the industry evolves, prioritizing sustainable practices will be essential in balancing the need for clean energy with the health of our planet.

Mitigating Environmental Risks: Best Practices for Sustainable Solar Energy

Implementing best practices in solar energy deployment can significantly mitigate environmental risks associated with solar panels. One of the prime concerns is the use of toxic materials in the manufacturing of solar cells. To address this, companies should prioritize the use of sustainable materials that minimize harmful waste. Employing a cradle-to-cradle approach can ensure that materials are reused or recycled rather than disposed of, thereby lessening the environmental impact. Additionally, facilitating transparency in the supply chain can help consumers make informed decisions about eco-friendly solar options.

Another vital aspect is the management of land resources during solar farm development. When selecting sites for solar installations, it’s crucial to assess the ecological value of the land. Utilizing degraded or brownfield sites for solar energy projects can reduce the need for land conversion and protect natural habitats. Moreover, implementing practices such as soil conservation measures and promoting biodiversity can help maintain the integrity of local ecosystems. Engaging with local communities during the planning stages can also foster collaboration and ensure environmental considerations are prioritized.

proper end-of-life management of solar panels is essential for sustainable energy practices. As solar technology advances, many panels will reach the end of their usable life. Companies should develop robust recycling programs to handle decommissioned panels, transforming waste into valuable resources. Establishing partnerships with recycling facilities can enhance recovery rates for precious metals and materials used in solar panels. Educational initiatives aimed at consumers and installers can promote awareness about recycling options, further enhancing the sustainability of solar energy systems.

0 Comments